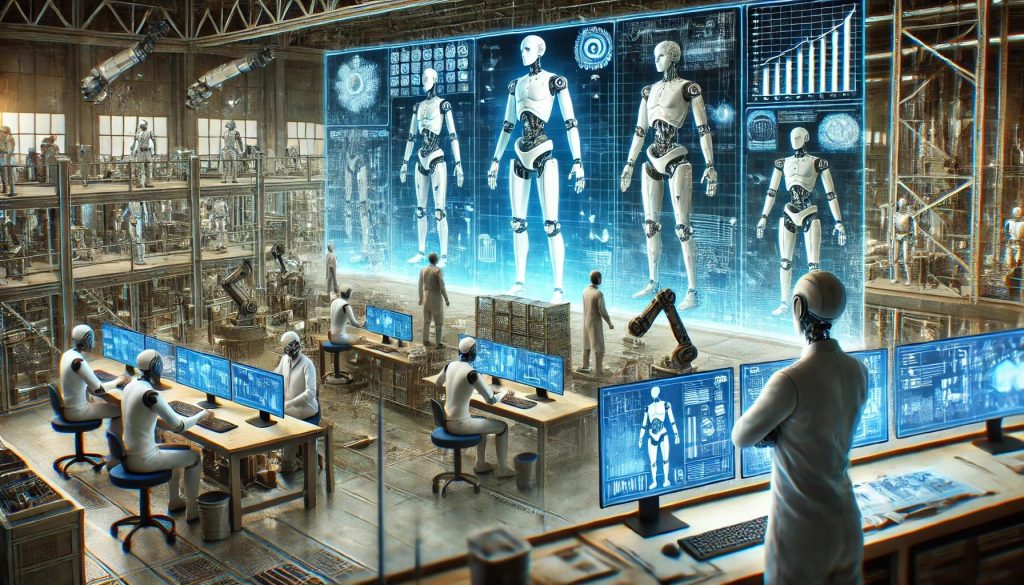

Humanoid robots are stepping into a new era of automation. In a groundbreaking move, factory trials have begun for robots capable of building replicas of themselves. This initiative promises to revolutionize the manufacturing industry, paving the way for more efficient and adaptive production systems. Moreover, it marks a significant milestone in robotics technology, demonstrating the increasing role of automation in our daily lives.

Apptronik and Jabil’s Strategic Partnership

Apptronik, an Austin-based robotics company, has partnered with Jabil, a leader in manufacturing solutions, to bring humanoid robots into factory lines. Their robot, Apollo, was unveiled in August 2023 and is designed for tasks that are dangerous, repetitive, or boring. Now, Apollo is set to enter mass production.

To achieve this, Jabil’s facilities will serve as real-world testing grounds. Here, Apollo robots will perform simple, repetitive tasks such as inspection, sorting, and fixture placement. If these trials prove successful, Jabil plans to manufacture Apollo robots, enabling the robots to assist in producing more units of themselves. Consequently, this would create a self-sustaining production cycle, revolutionizing the manufacturing process (Business Insider).

Implications for the Manufacturing Industry

This development could have a significant impact on the manufacturing industry. By automating repetitive tasks, human workers can focus on more creative and complex projects. As a result, productivity and job satisfaction could see a notable increase.

Furthermore, deploying robots capable of building replicas of themselves could lead to exponential growth in automation capabilities. This advancement would reduce production costs and time, making the manufacturing process more streamlined and cost-effective. In addition, it could enhance scalability, enabling companies to quickly adjust production volumes based on market demands (Business Insider).

Advancements in Humanoid Robotics

Apptronik’s initiative is part of a broader trend in humanoid robotics. For example, companies like Agility Robotics have introduced robots like Digit, which are now performing real jobs in distribution centers. These robots handle routine and laborious tasks, bridging the gap between specialized automated machines and human versatility.

Moreover, the push for cost-effective, mass-produced humanoid robots has been driven by advances in artificial intelligence and reduced component costs. This technological progress makes them more practical for industries like e-commerce and manufacturing, where adaptability and efficiency are crucial. As a result, humanoid robots are becoming an integral part of modern industrial ecosystems (Wall Street Journal).

Challenges and Future Outlook

While the concept of robots building themselves is promising, several challenges remain. First and foremost, ensuring reliability and precision in manufacturing settings is crucial. Additionally, addressing ethical considerations and potential job displacement is essential as automation becomes more prevalent.

Despite these challenges, the successful implementation of self-replicating robots could pave the way for more resilient and adaptive manufacturing systems. Consequently, this could transform the industry landscape, fostering a new era of automation and efficiency. Moreover, it could inspire further innovation in robotics and artificial intelligence, expanding the potential applications of humanoid robots.

Conclusion

In conclusion, the factory trials of humanoid robots capable of building more of themselves mark a significant milestone in robotics and manufacturing. As these technologies continue to evolve, they hold the potential to redefine production processes, enhance efficiency, and unlock new opportunities for human creativity and innovation.

Therefore, this initiative not only showcases the progress of robotics technology but also highlights the increasing importance of automation in shaping the future of work. Ultimately, it could lead to a more efficient, adaptable, and innovative industrial landscape.